The Floating Foundation *BRUNEL*

The BRUNEL floating foundation is designed to unlock the potential of floating wind.

A floating wind turbine foundation with both strong technical and commercial capabilities, BRUNEL is designed for the next generation of wind turbines. BRUNEL has a modular approach suitable for serial and automized production in the existing global supply chain allowing for instant scale-up and low cost.

A Pioneering Floating Foundation Based on Tubulars

The BRUNEL Floating Foundation is a semi-submersible structure designed for harsh north-sea conditions.

With its modular design, the philosophy is to utilize existing and proven technology to allow for a rapid route to market. The use of modular steel tubulars, like the ones used for monopiles and wind towers, means that BRUNEL is manufactured and designed for the existing global supply chain, and with a radical focus on automated mass production.

Subsequently, BRUNEL can leverage already existing supply chains and manufacture and assemble foundations at the volume required for floating giga-parks. Additionally, BRUNEL offers more efficient logistics and the facilitates local content assembly.

BRUNEL awarded DNV Basic Design Certification

Fred. Olsen 1848 is pleased to announce that BRUNEL Floating Foundation, a leading initiative in the floating offshore wind market, has completed its comprehensive basic design phase according to DNV’s recently updated certification scheme for floating wind, DNV-SE-0422, and was subsequently awarded a DNV Basic Design Certification as one of few foundation designs in the industry.

Read full press release here: BRUNEL DNV Certified

*BRUNEL Maintenance Solution*

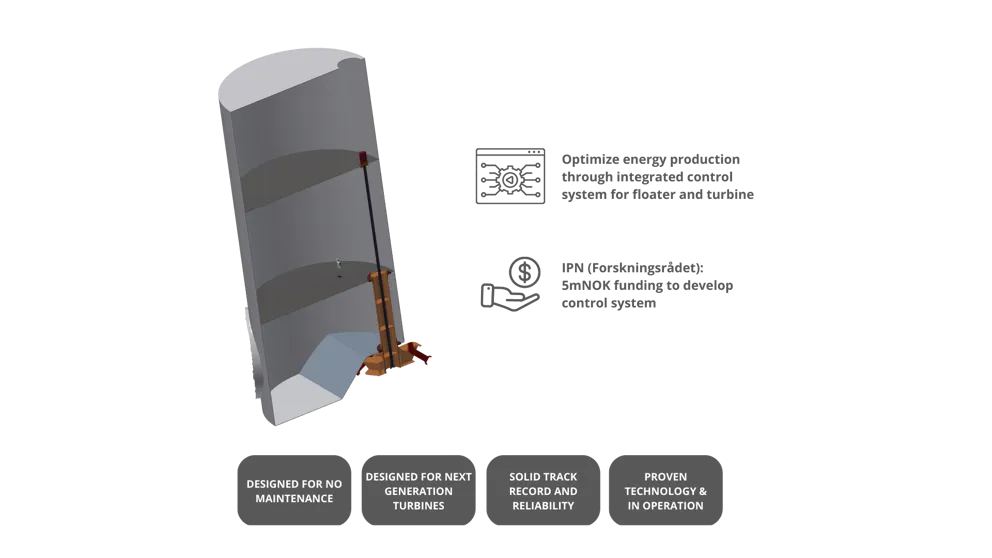

Fred. Olsen 1848 is developing an O&M solution tailored specifically for BRUNEL – a complete solution and operational procedure.

The BRUNEL Maintenance Solution will enable large component exchange directly at the offshore floating wind site in a safe and cost-efficient manner, operationally optimized for the BRUNEL floating foundation. This reduces project risk and avoids towing the foundation to shore.

The unique BRUNEL maintenance solution features a barge fitted with both a jacking system and a compatible crane that attaches itself to the BRUNEL foundation. This removes the need for dynamic lifts, reduces complexity in replacement operations, and at the same time creates a working area on the barge to handle the components.

BRUNEL EXPLAINED

Rethinking Floating Offshore Wind

Unlike conventional single-tower floating foundations, the BRUNEL floating foundation has dual towers as an integral part of the design to reduce interface risks, enhance stability, and provide greater design flexibility, allowing for larger turbines without exceeding fabrication limits.

Moving Intelligently Towards the Wind Thrust Force

Fred. Olsen 1848 and partners have developed a framework for the "Active control of yaw drift in single-point moored wind turbines."

This approach helps to stabilise floating wind turbines whilst optimising their positioning against wind thrust, resulting in improved energy generation.

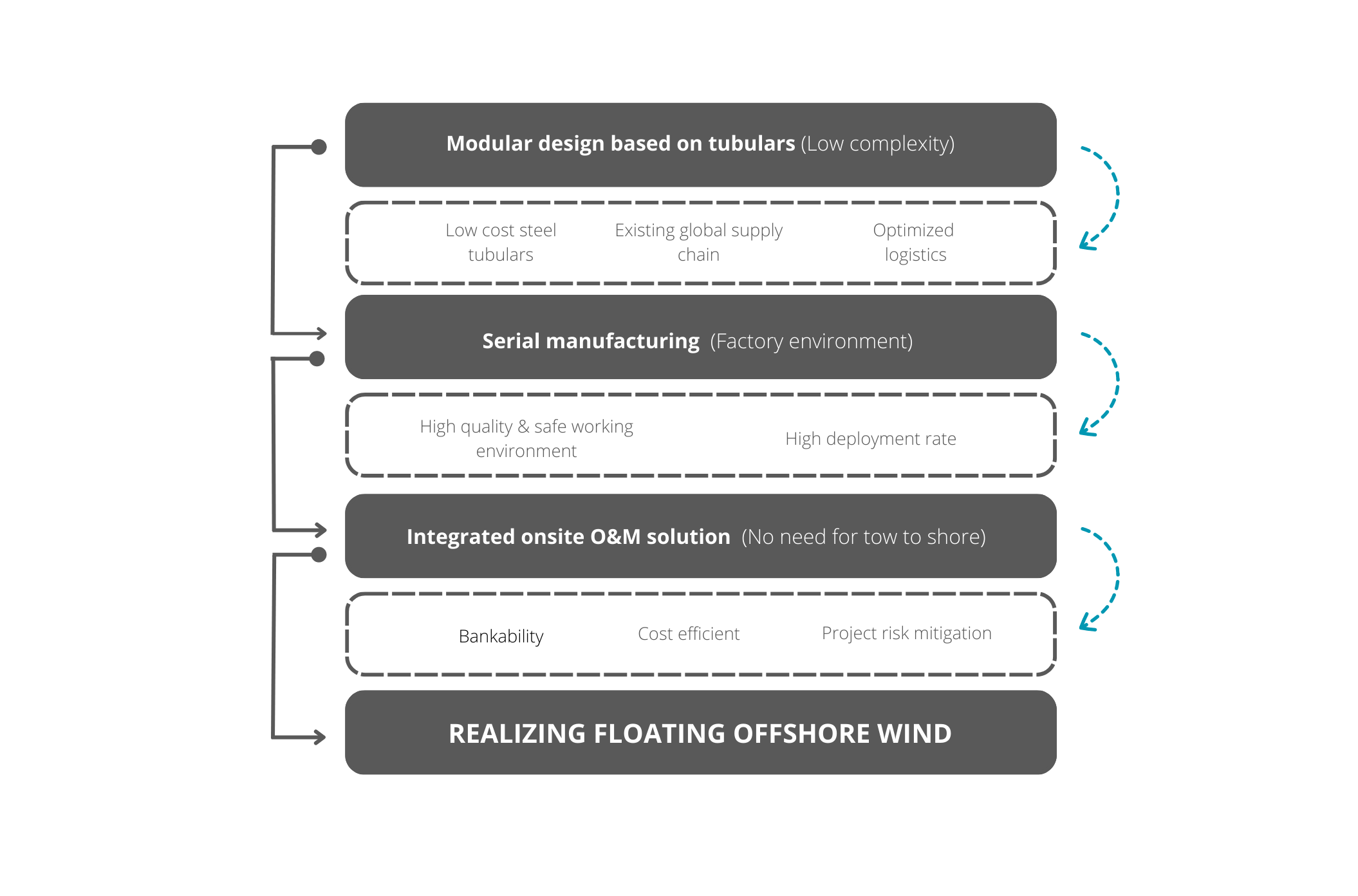

The BRUNEL drivers

The modular design of BRUNEL based on steel tubulars offers low complexity and benefits from a competitive cost per fabricated ton. The low-cost steel tubulars utilize the existing global supply chain, and the modularity enables optimized logistics.

BRUNEL’s design allows for high-quality serial manufacturing in a safe working environment in controlled factory conditions. This facilitates a high deployment rate.

To avoid towing the foundation to port, an integrated onsite maintenance solution is under development. This enables large component exchange directly at the floating offshore wind site in a safe and cost-efficient manner.

The combination of the above benefits makes the BRUNEL foundation stand out with the ability to realize the potential of floating offshore wind.

The design of BRUNEL is based on a simple, yet challenging design philosophy: to see if we can build a foundation based on generic steel tubulars and hence enable manufacturing at a commercial scale. This radical focus on commercial requirements, while at the same time attending to excellence on all technical parameters, will allow the floating offshore wind industry to realize its enormous potential.

BRUNEL utilizes proven technology and leverages the existing supply chain. Its structure is optimized for the wind thrust force, featuring a modular design structure.

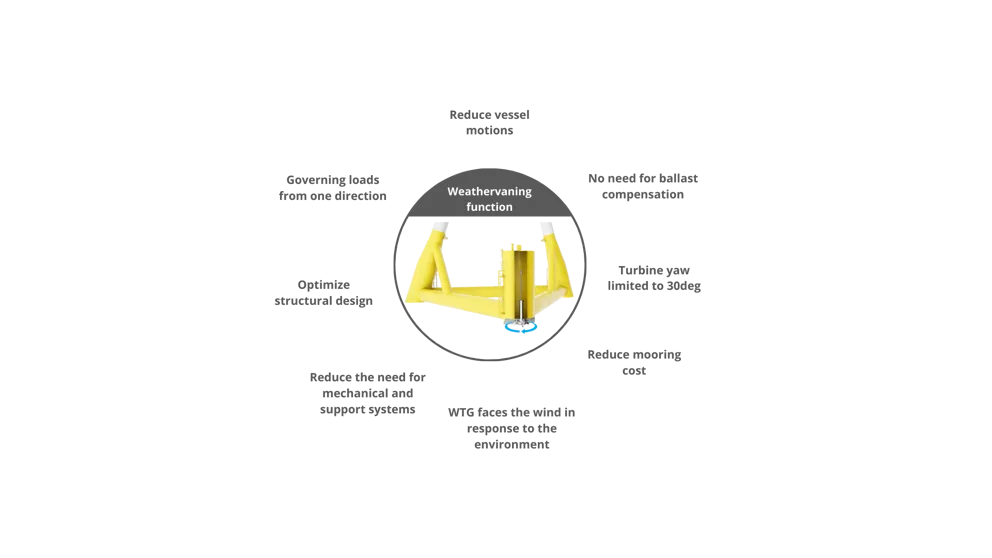

Turret with low complexity

The BRUNEL floating foundation features a single-point mooring through a turret. This system builds on years of experience within turret mooring systems in O&G, however, this turret is made in a simplistic manner. The turret is designed with low complexity ensuring reliable operations.

The weathevaning function allows for a passive ballast system and a structure that continuously optimizes its position towards the wind thrust force. Said differently, this means BRUNEL can self-align towards the wind direction.

The single-point mooring system creates cost-reducing benefits by reducing the need for mechanical systems and reducing mooring costs.

BRUNEL builds on the heritage of Fred. Olsen related companies

Brunel is developed on the back of our strong engineering and maritime heritage and leverages the renewable ecosystem of the Fred. Olsen-related companies.

Learning from bottom-fixed offshore wind, a high level of automized and serial manufacturing is needed to reduce the LCoE whilst ensuring high deployment rates, high quality and a safe working environment.

The BRUNEL floating foundation realizes floating offshore wind by:

- utilizing Fred. Olsen’s long heritage and knowledge from the maritime and energy sector

- being developed to produce for high-volume serial manufacturing facilities in a fully controlled factory environment

- allowing for efficient transportation, logistics and local final assembly

If you have any questions about BRUNEL floating foundation, please get in contact.

Latest News

Introducing Tension Buoy: Unlocking Floating Solar and Hydro Power Potential

Oct 07, 2025

There’s an increasing need for a fresh approach to floating design and strategy

Jun 05, 2025

Upgrading Floating Modules on the Pilot of BRIZO: An Interview with Our Project Manager

Jan 21, 2025

BRUNEL Floating Foundation Completes DNV Basic Design Certification

Oct 31, 2024

NEWS UPDATE: Fred. Olsen 1848 has deployed the Floating PV Technology BRIZO in Risør, Norway

Feb 01, 2024

Fred. Olsen 1848 welcomes Per Arvid Holth as its new CEO. He succeeds Sofie Olsen Jebsen and will take up the position on 1 March 2024.

Jan 10, 2024