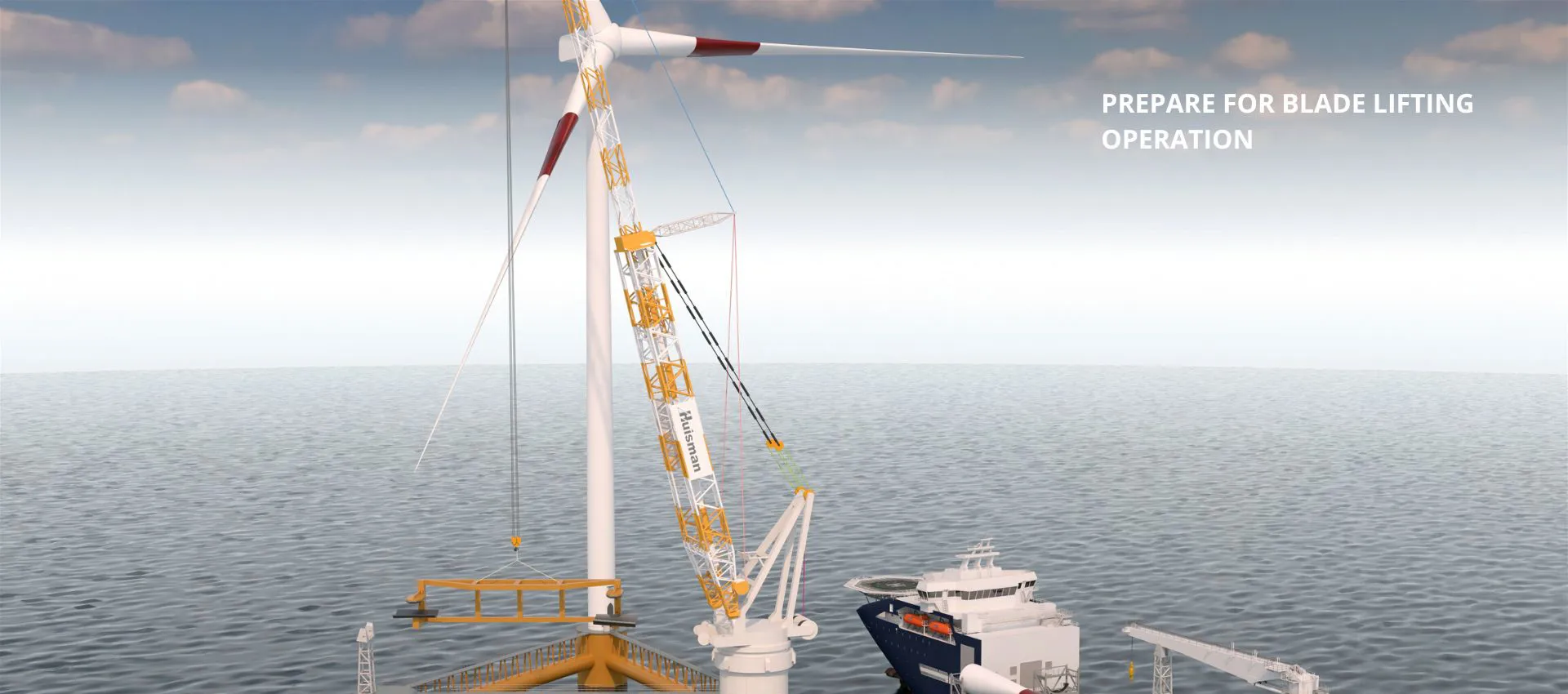

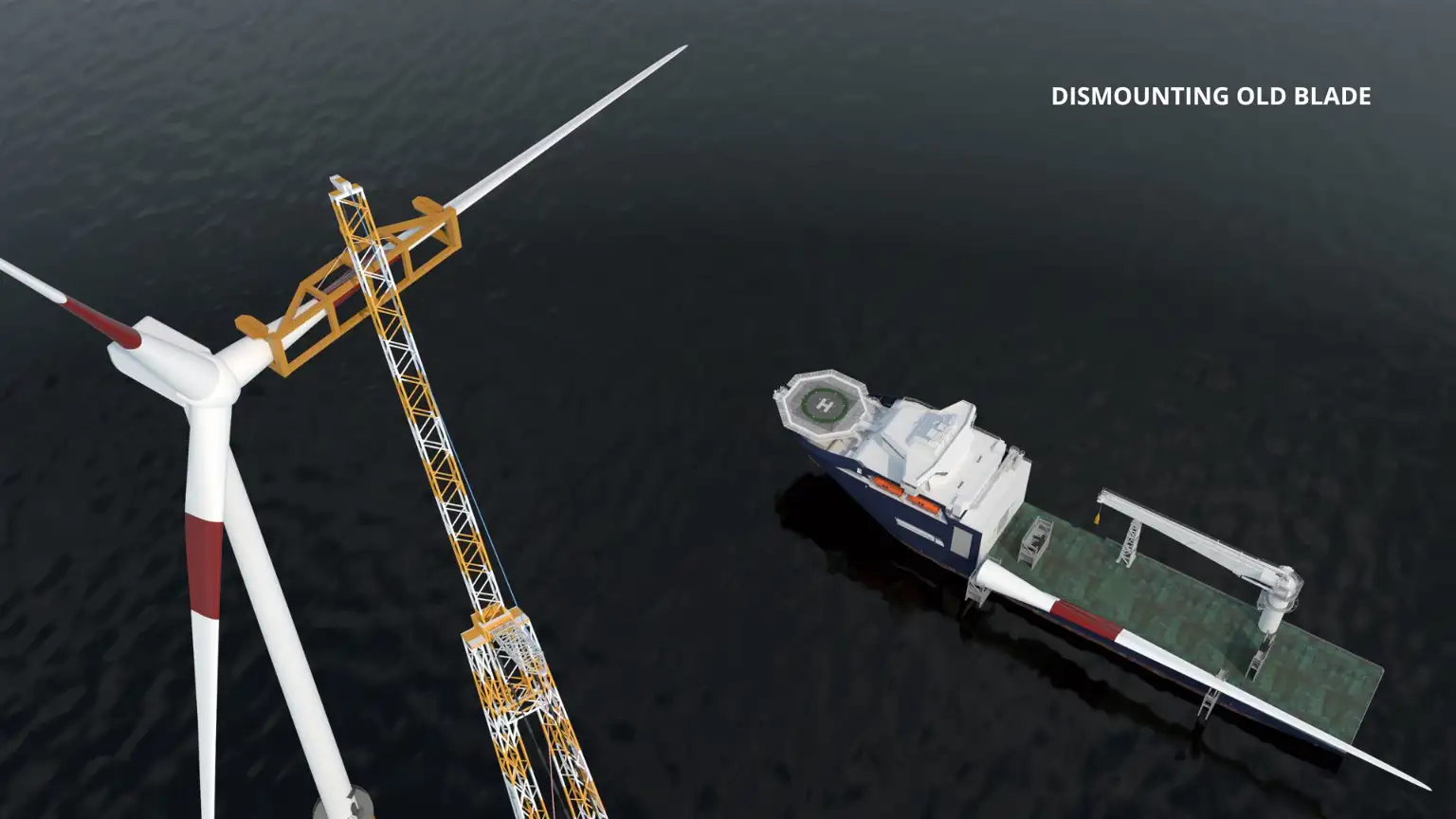

*Floating Maintenance* Solution

A solution to solve the challenge of major component exchange at the floating wind site, to unlock the potential of floating wind.

Solving the *maintenance challenge* in floating wind

Fred. Olsen 1848 has developed the patent pending Floating Maintenance Solution.

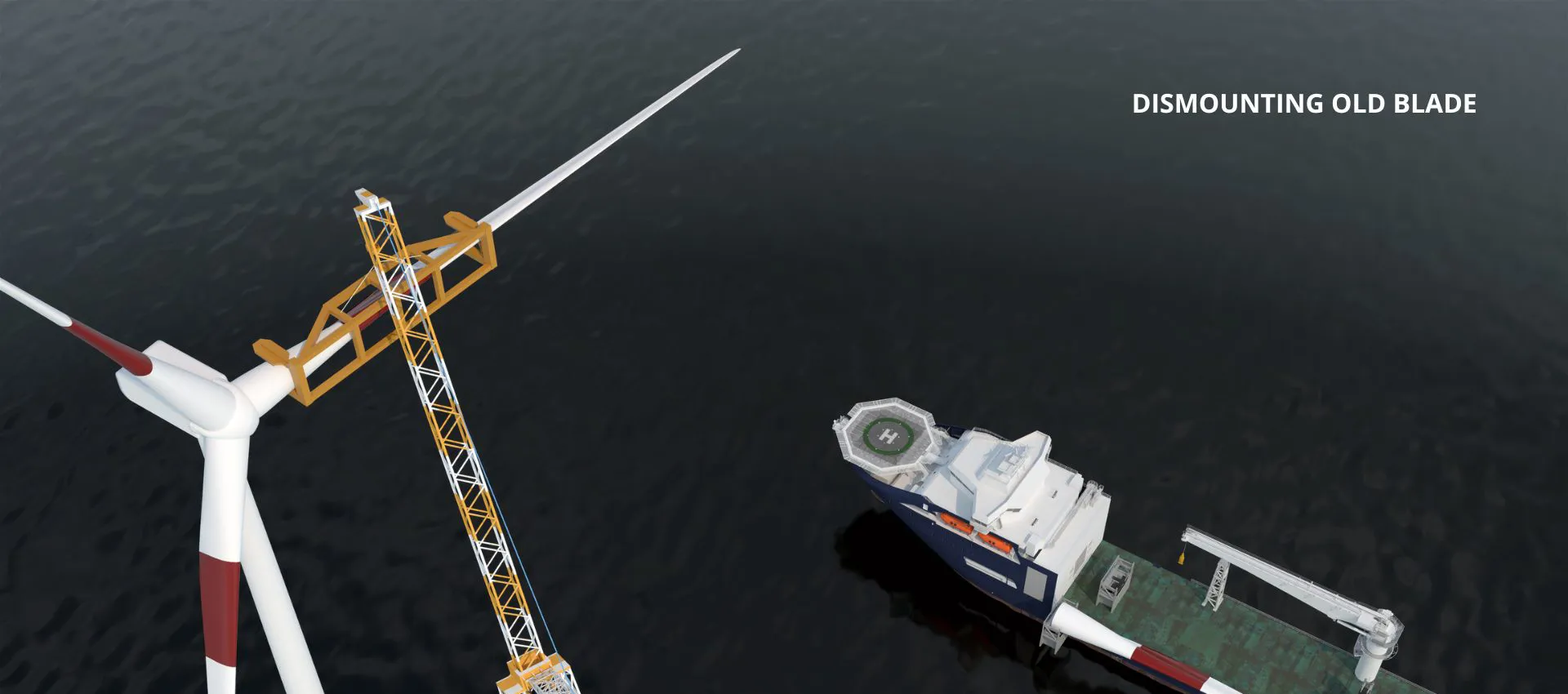

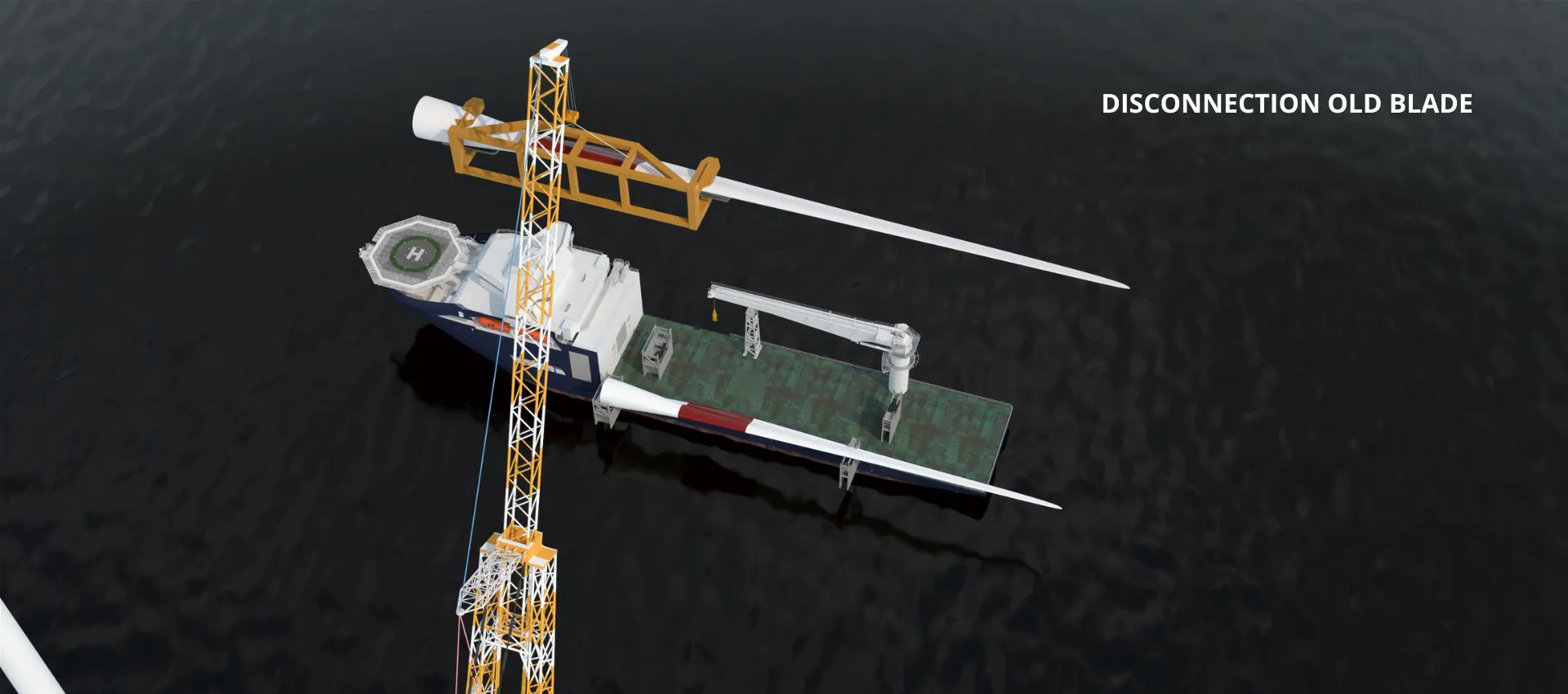

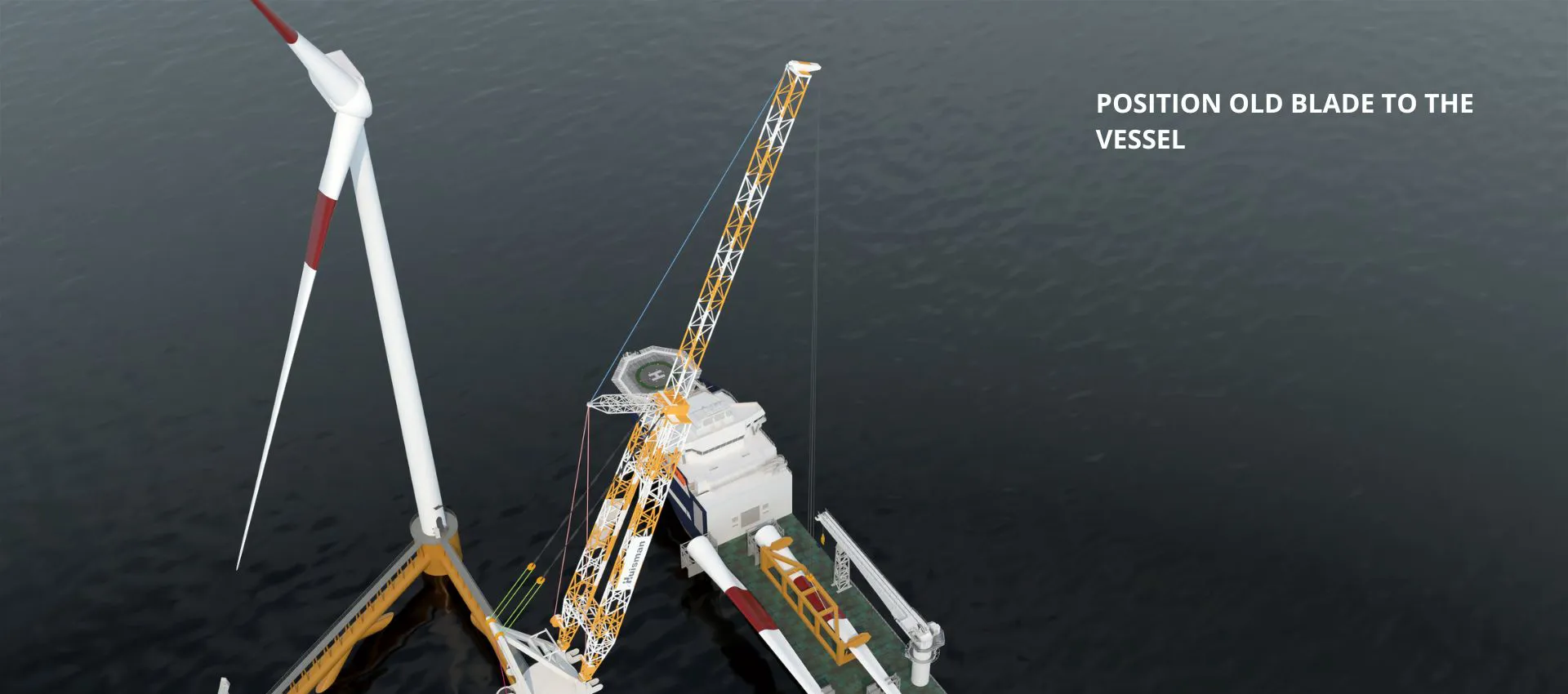

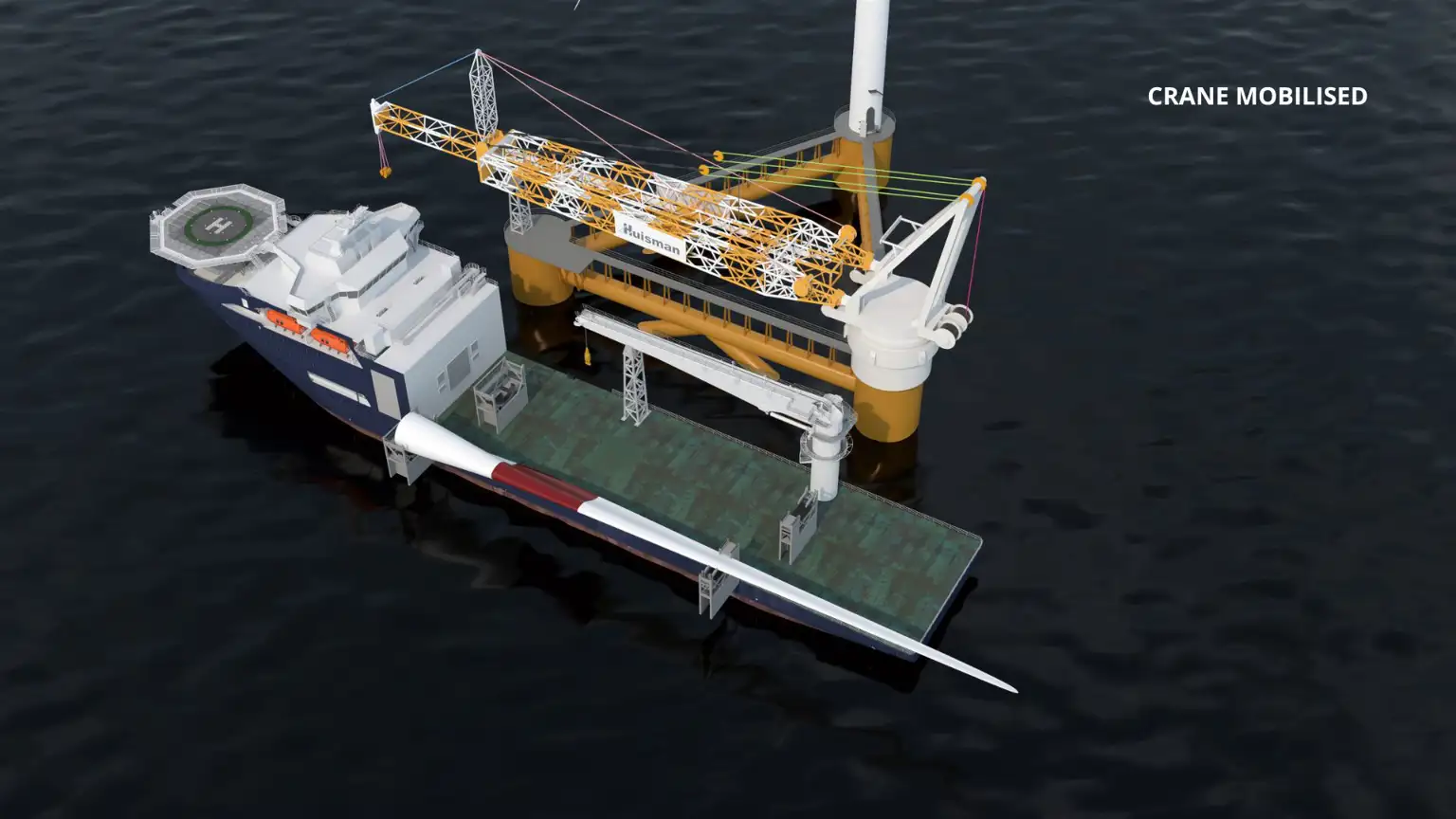

The solution utilizes existing vessels and methods in the industry today and centralizing around a state-of-the-art maintenance crane.

The solution is compatible with most semi-submersible floating structures in the market, with a minimal requirement for modifications on the floating foundations.

The solution grants the flexibility to perform operations across several projects with various types of floating foundations.

"The present floating wind component exchange solutions are too costly in terms of assets required, downtime of the turbine and available weather windows. We believe the Floating Maintenance Solution will be a game-changer in the market and can enable the industrialisation of floating offshore wind."

- Per Arvid Holth, CEO of Fred. Olsen 1848

O&M activities

carried out on site

Well-known

crane technology and lifting operation

Efficient

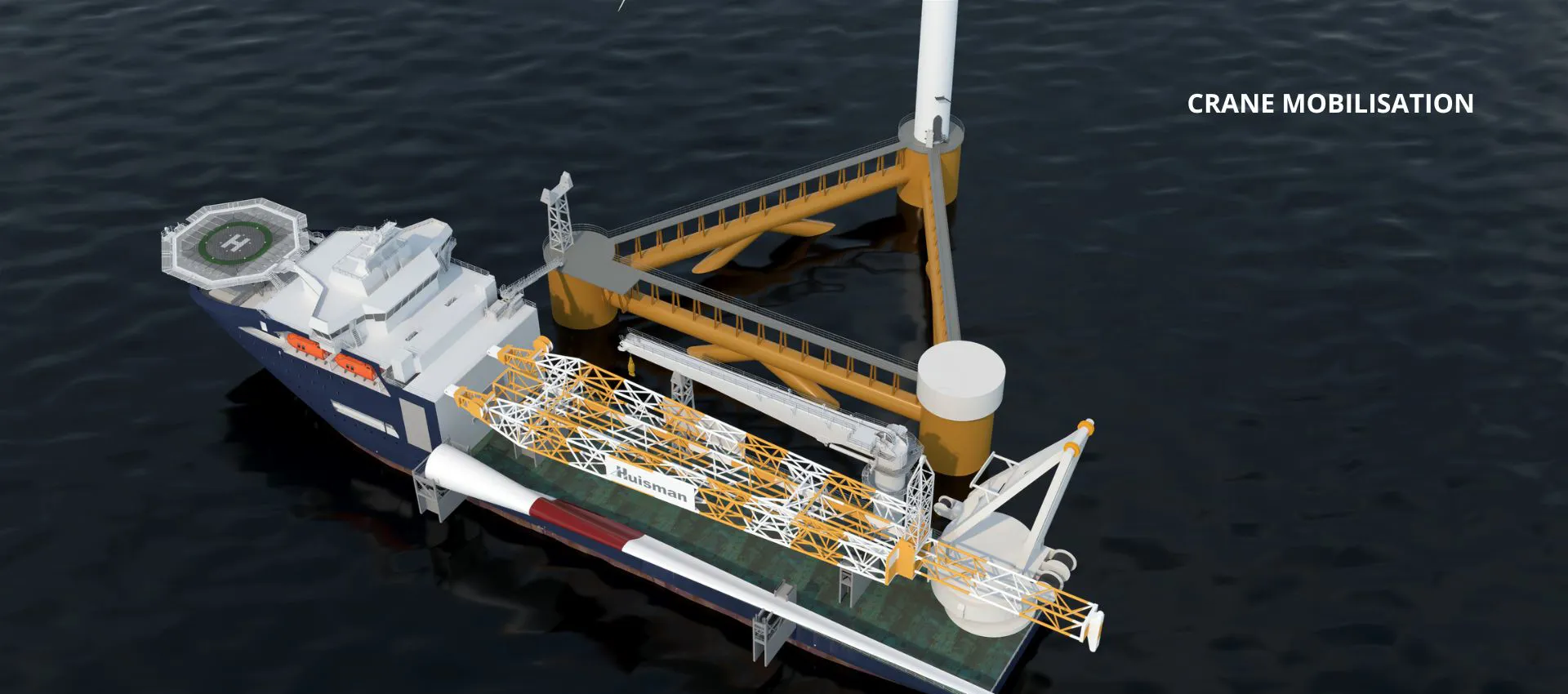

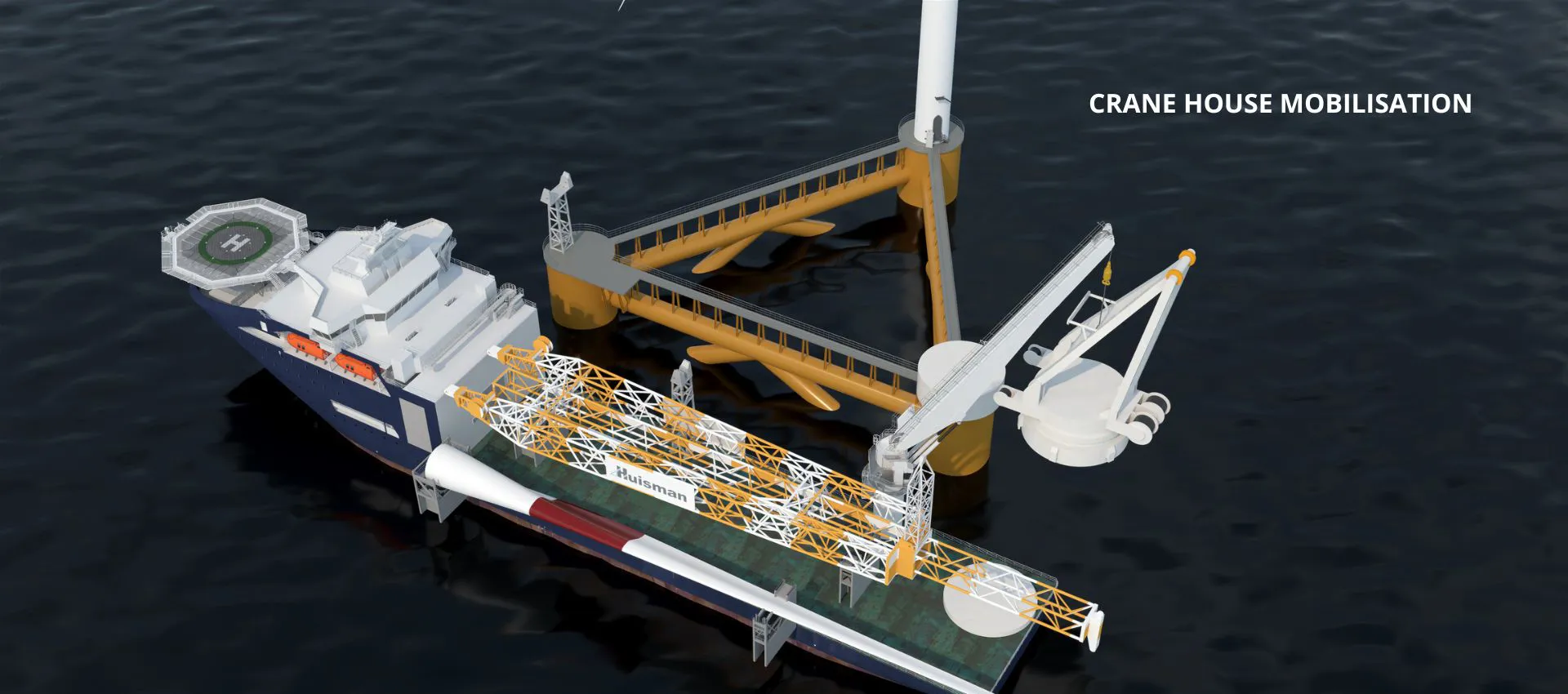

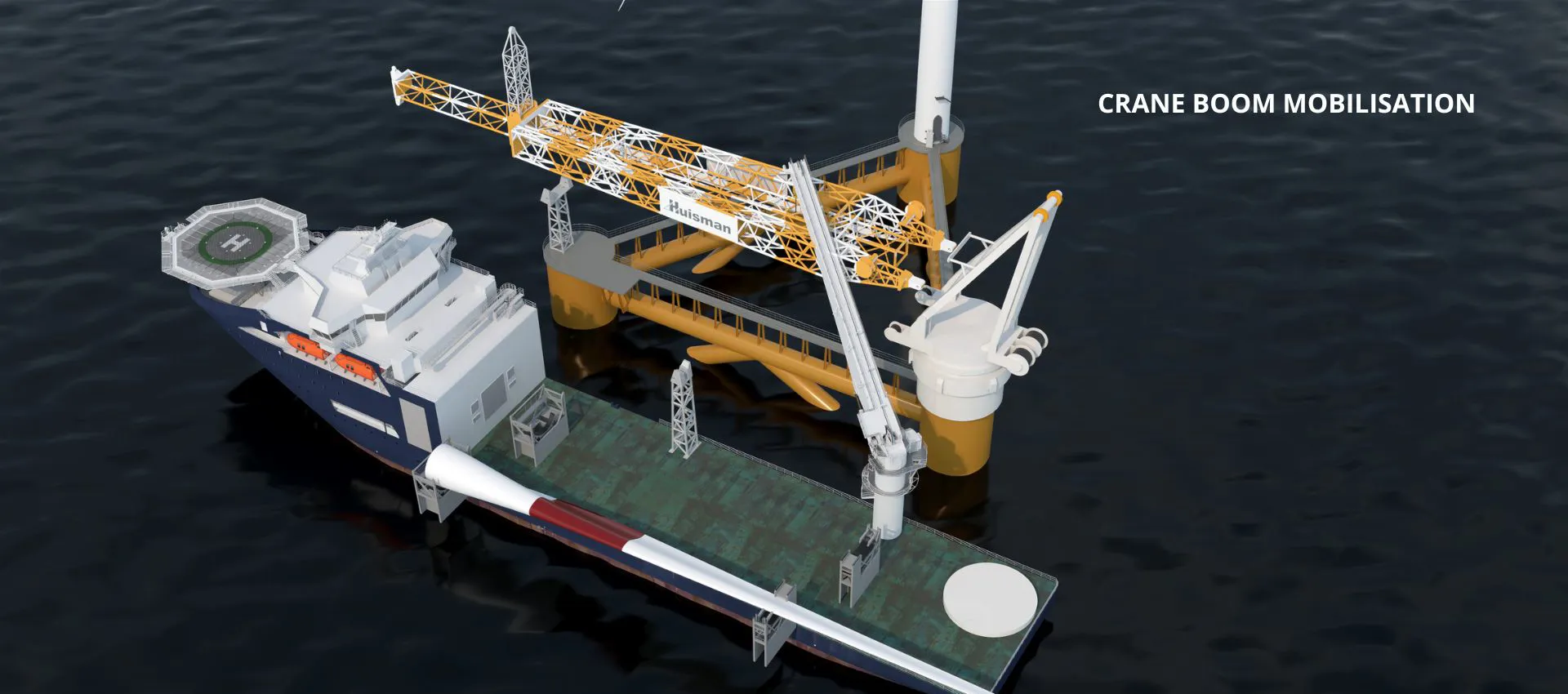

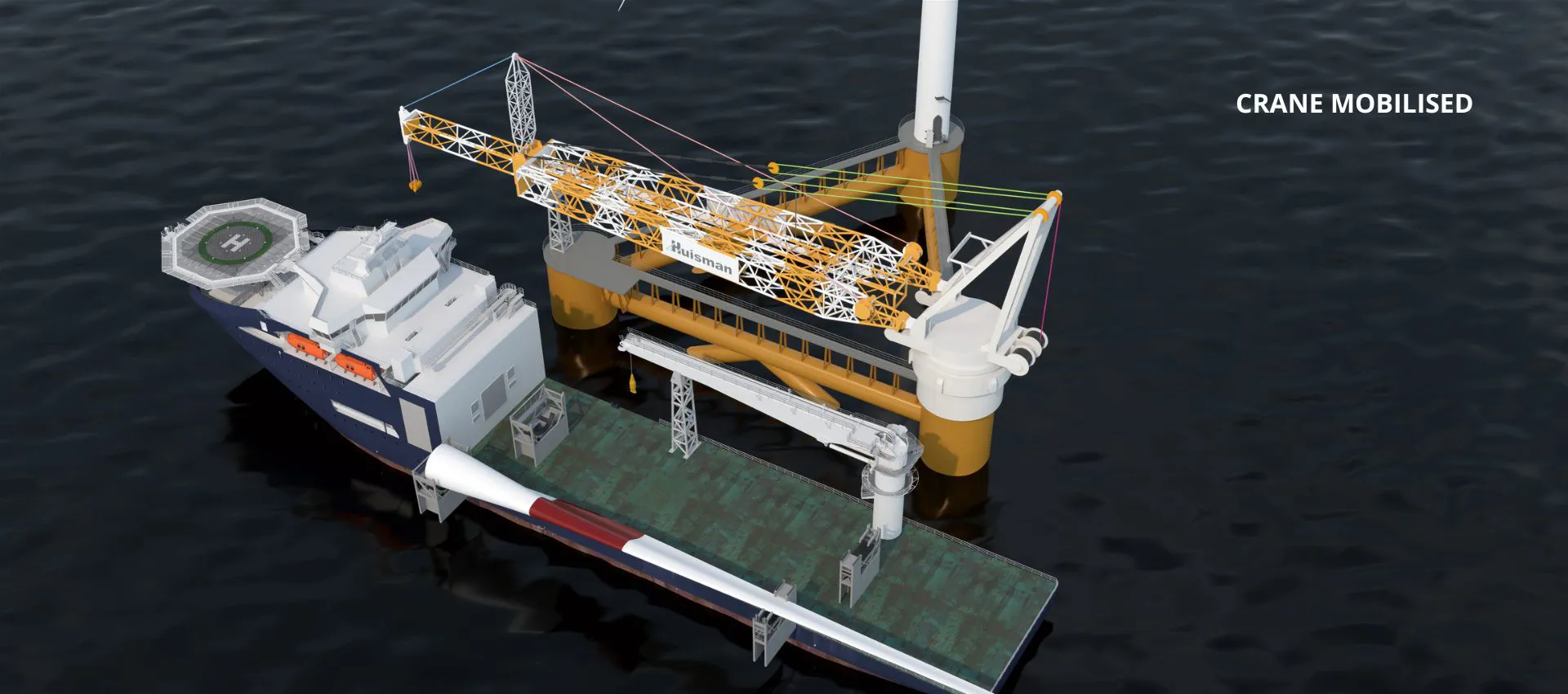

mobilization

No changes

on tower or WTG

Agnostic

to most semi-submersible foundations

Minimal

modifications to the floater

Operates

with same motions as floater

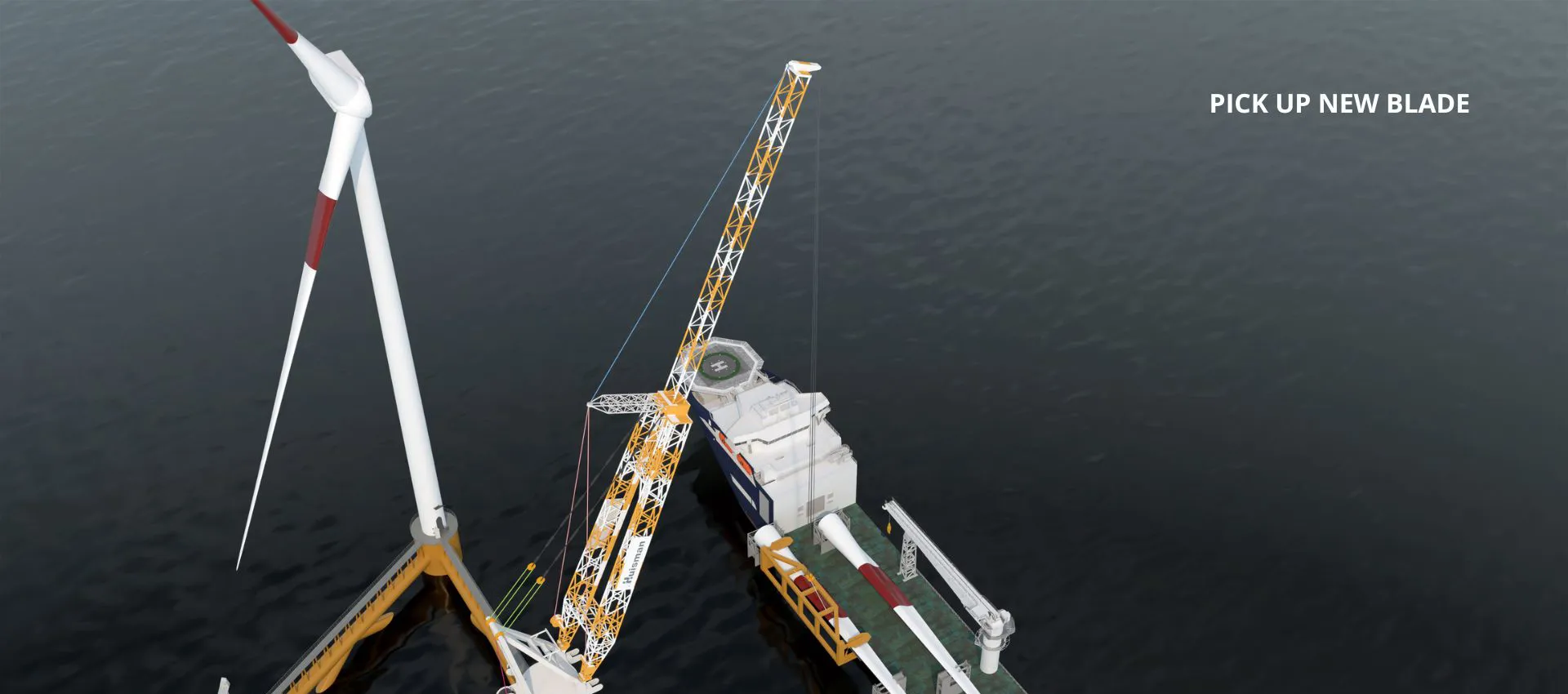

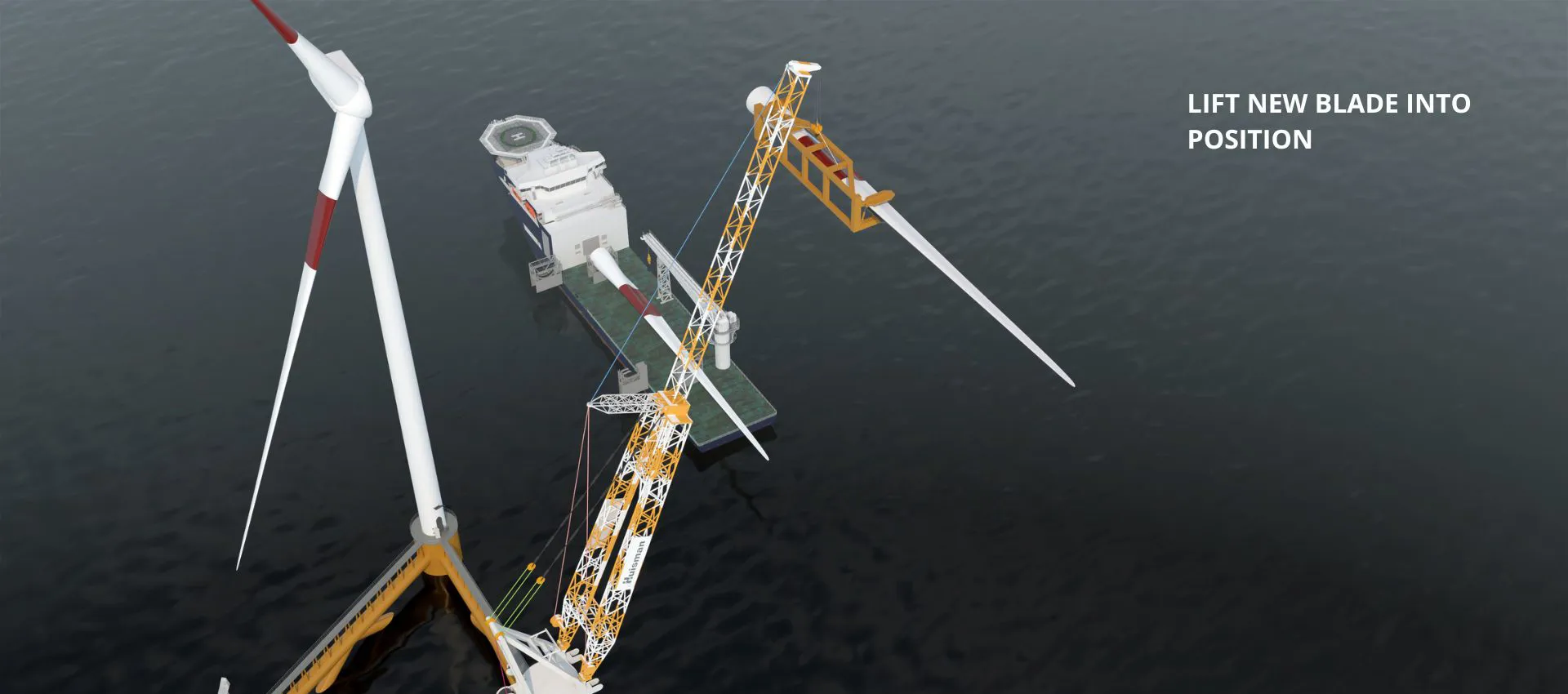

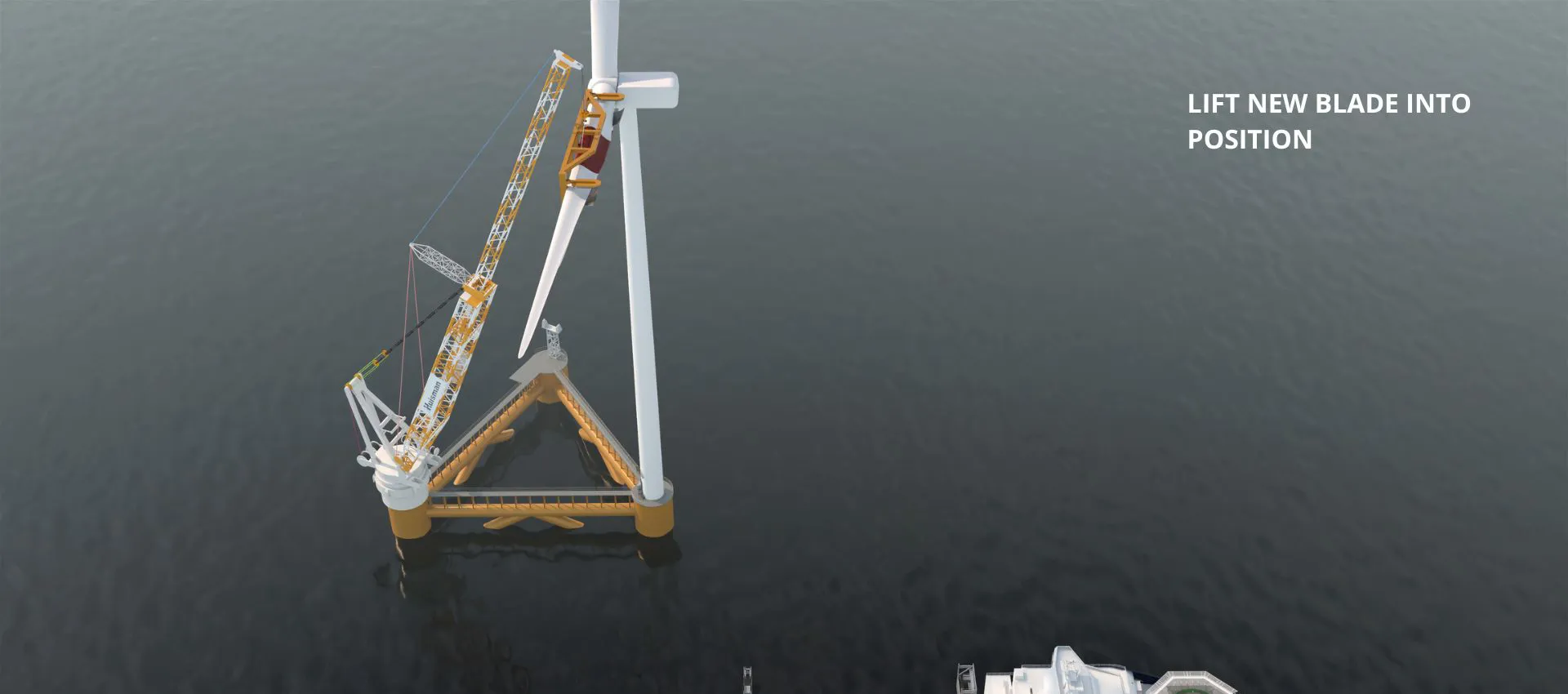

State-of-the-art maintenance crane engineered and developed by Huisman featuring:

- An expandable main boom and a foldable knuckle boom integrated in a compact self-supporting setup, to be transported safely and efficiently.

- A unique quick connection system, allowing the crane to be deployed in multiple lightweight modules, and such that it can be quickly deployed on any floating foundation prepared for this setup.

- An all-electric drive system, resulting in high positioning accuracy, low energy use, reduced maintenance, and high reliability.

- A dedicated energy storage system, allowing the crane’s power supply to come from the turbine’s auxiliary circuits, yet having sufficient energy available for crane operations.

- Well-known crane technology.

- Well-known lifting operation.

- The crane is capable of lifting components up to 150m above the foundation level. Larger versions can be made available when turbines would grow in the future.

News

Introducing Tension Buoy: Unlocking Floating Solar and Hydro Power Potential

Oct 07, 2025

There’s an increasing need for a fresh approach to floating design and strategy

Jun 05, 2025

Upgrading Floating Modules on the Pilot of BRIZO: An Interview with Our Project Manager

Jan 21, 2025

BRUNEL Floating Foundation Completes DNV Basic Design Certification

Oct 31, 2024

NEWS UPDATE: Fred. Olsen 1848 has deployed the Floating PV Technology BRIZO in Risør, Norway

Feb 01, 2024

Fred. Olsen 1848 welcomes Per Arvid Holth as its new CEO. He succeeds Sofie Olsen Jebsen and will take up the position on 1 March 2024.

Jan 10, 2024