• Blow- and injection molding

BRIZO’s design uses well-established fabrication methods, including blow- and injection molding. The floating modules are manufactured using processes akin to those employed in the production of water bottles. Furthermore, the system utilizes recycled materials, and moreover, all components used for BRIZO can be readily recycled at the end of their life cycle.

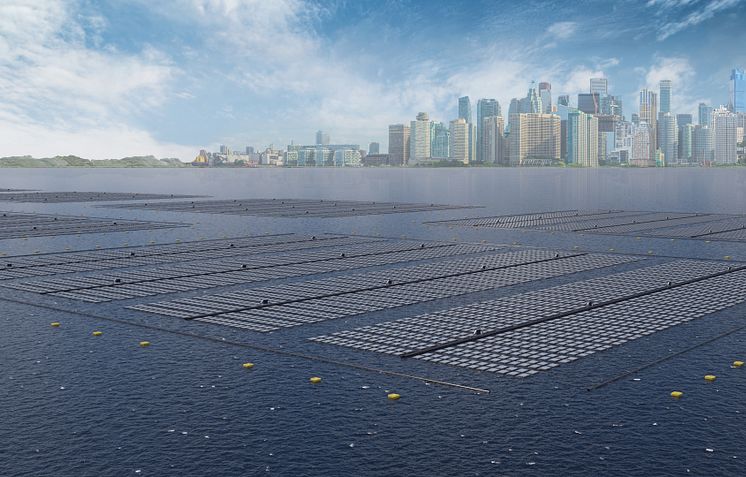

• Assembly with limited infrastructure

BRIZO offers a distinct advantage in floating solar solutions as it allows assembly in areas with limited space, infrastructure, and without the need for heavy equipment. This makes BRIZO a globally versatile solution, suitable for assembly in diverse locations.